In the food industry, even more than in other sectors, the cleanliness of working environments is fundamental to ensure total product safety. The use of gases ensures flawless results: cryogenic cleaning in the food industry proves to be an advantageous solution. Taking advantage of the intelligent action of CO2 results in clean, residue-free surfaces and machinery. And the process is environmentally friendly.

In this article, we will find out what cryogenic cleaning is, how it works, and all the benefits to the food industry.

Cryogenic cleaning, what is it

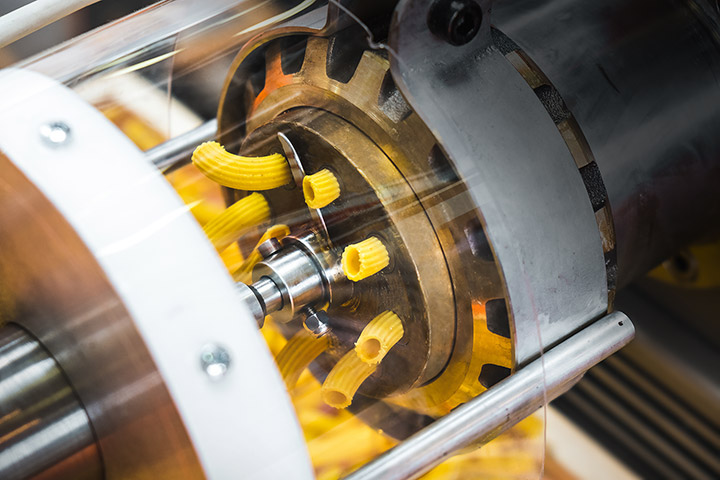

Cryogenic cleaning or cryosandblasting, also known as dry ice blasting, involves projecting small pellets of dry ice at a temperature of -78.5°C onto the surface to be treated at sonic or supersonic speed. Combined mechanical and thermal effects, generated by speed and low temperatures, are particularly effective in multiple applications and industries for environmentally friendly cleaning.

The dry ice used in cryogenic cleaning is nothing but liquefied carbon dioxide gas, expanded, solidified and reduced into small pellets.

These projected onto the surfaces allow deep cleaning: by cooling the surface layer to be removed, they break the adhesion bonds favoring removal.

Cryogenic cleaning is green

In addition to being clean and safe, dry ice is also environmentally friendly. In fact, the carbon dioxide useful in its generation is obtained as a by-product of other industrial processes. So, no new CO2 is produced, but it is transformed into another form and, therefore, does not contribute to the increase in greenhouse gas concentration.

Cleaning with dry ice: all the advantages

Cryogenic cleaning, besides being high-performance, is flexible. In fact, it is suitable for so many sectors: from pharmaceuticals to the wood, rubber and plastic industries, through mechanical, manufacturing, and marine.

In the food industry, the advantages of cryogenic dry ice cleaning, as well as in other industries, are many:

- Cleaning with a natural substance: Cryoblasting replaces cleaning with chemicals and solvents. It uses CO2 pellets made from the same substance used to carbonate drinks. Food security, therefore, is total.

- No waste: Unlike cleaning with sand, soda, water or grit, cleaning with dry ice generates no secondary waste.

- Safety on electrical components: Cryogenic cleaning eliminates significant buildup without damaging delicate parts, such as electrical components, switches, wires, photoelectric sensors, etc.

- Thorough and deeper cleaning: Because dry ice pellets can reach every corner of the equipment, they clean deeper and more effectively.

- No harm: Cryoblasting is a completely dry, nonabrasive, nontoxic, and noncorrosive process. It quickly removes most contaminants without damaging switches, panels, lines, pipes, cables, belts or HVAC systems and is safe on electrical components.

- No production downtime: The process is extremely fast and dry. Dry ice sublimates on contact, and cleaning can be done in-line without the need to disassemble components and wait for them to dry.

Cryogenic cleaning, SIAD’s solutions for the food industry

SIAD has developed cryogenic cleaning solutions that meet the needs of the food industry. Simply connect the machine to the utilities required for its operation and by loading it with dry ice pellets, cleaning is very easy thanks to the gun and nozzles that allow it to reach even the least accessible spaces.

Dry ice supply is simple: to meet the diverse cold needs of its customers, SIAD has developed the ICEandGO service that provides direct delivery of dry ice, even in small quantities.