Greater attention to food quality and healthfulness characterize the expectations of a growing number of consumers. For food and retail operators, giving adequate responses to these renewed consumer needs is, now more than ever, a priority.

The focus is on the cold chain, the steps between production and consumption: it is at these stages, the most critical, that processes of deterioration of the nutritional properties of the food must be avoided, maintaining a correct and constant temperature in order not to affect the organoleptic qualities and prevent the development of bacteria.

If we add to this, in parallel, that habits in terms of flexibility have also changed, with demands changing the traditional canons associated with locations and timing of consumption, it is clear that the need to offer delivery services with high standards, involving the entire supply chain and particularly refrigerated transport systems, is increasing for companies in the industry.

SIAD has employed all the know-how gained from nearly a century of experience in cryogenic gas industry and applications to meet the needs of the logistics and refrigerated transport sector by conceiving, designing and developing an innovative technology dedicated to refrigerated transport in roll containers: COOOL® RollBox.

As with COOOL® FreeToGo, the technology designed for improvements in refrigerated road transport, this line overcomes the limitations of current systems and harnesses the refrigeration power of CO2, produced in-house, bringing concrete solutions to the most common limitations in the industry:

- Effectively ensure the cold chain

- Simplify logistics management

- Increasing the autonomy of cold

- Use versatile multi-temperature systems

- Limiting investment dedicated to transportation

So the cold chain is really efficient

To be efficient, the cold chain must ensure that products are maintained throughout the entire journey from production to sale, including transportation, storage and display, ensuring maximum shelf-life. Deviation from the correct temperature during transport stages could promote, to a greater or lesser degree depending on the temperature change and duration of exposure, both the deterioration of products and the proliferation of microorganisms harmful to human health.

COOOL® RollBox can perfectly adapt to all needs of cold logistics, from the food supply chain to the large-scale retail trade. The refrigerated drawer fixed inside the isothermal container behaves as if it were a eutectic plate, but, unlike the traditional solution, it has more power and consistency in the emission of frigorifics. This allows the goods to be guaranteed to be stored longer.

How COOOL® RollBox Works

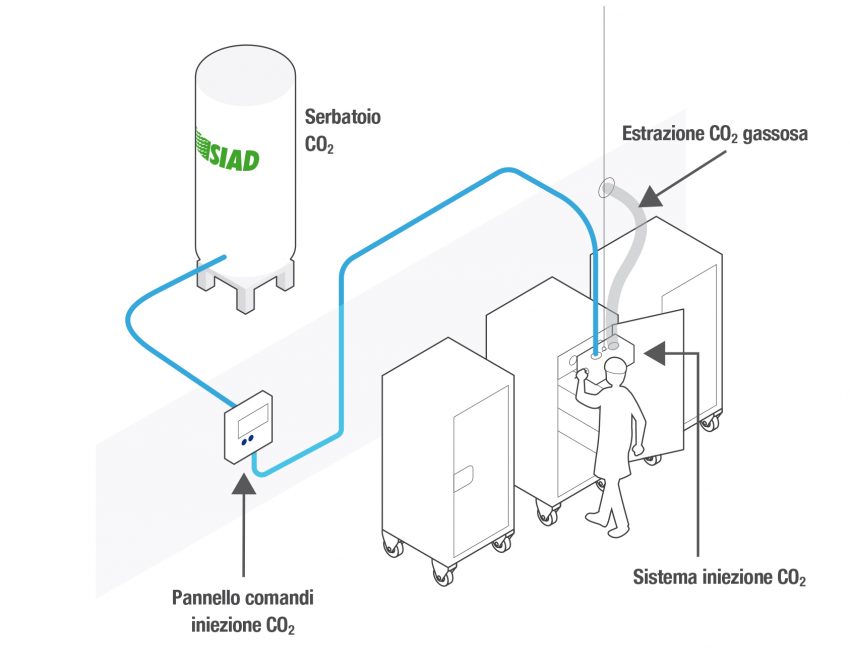

COOOL® RollBox efficients processing time and enables simplification in cold chain management: with this system, it will no longer be necessary to pre-cool and transport heavy and bulky eutectic plates; instead, simply connect the fitting and inject the required amount of CO2 directly into the drawer.

In addition, thanks to the external control panel, different dispensing can be managed according to the type and duration of transport, and by immediately obtaining the necessary refrigeration, it enables important resource optimization.

How to recharge

The charging mechanism is simple and intuitive, has an electromagnetic safety connection, and an automatic extraction system for the gas-phase CO2 created during the carbon snow generation process.

The insulating lining of the drawer ensures that the correct amount of cold is transmitted to the compartment below.

Refrigerated transport in roll containers: the advantages of COOOL® RollBox

The renewal proposed by COOOL® RollBox, therefore, breaks down the limitations of the traditional refrigerated transport system in roll containers by providing numerous advantages.

Flexibility and efficiency

A key feature of COOOL® RollBox is the ability to adapt to the contingent needs of companies, including, in a single system, the ability to transport fresh, frozen or both. In fact, it allows bi-temperature transport even with single-temperature vehicles.

This flexibility is tied in parallel with the efficiency provided by the reduction in the number of activities required to transport cold that actually simplifies logistics management exponentially. Depending on transport conditions, it is possible to recharge the system very quickly with the appropriate amount of dry ice.

High performance and safety

Dry ice generated and used in COOOL® RollBox guarantees consistent, long-term temperature control, resulting in more consistent frigor release.

In addition, the charging system is equipped with all appropriate personnel safety systems, and the CO2 supplied can be food grade, certified E290.